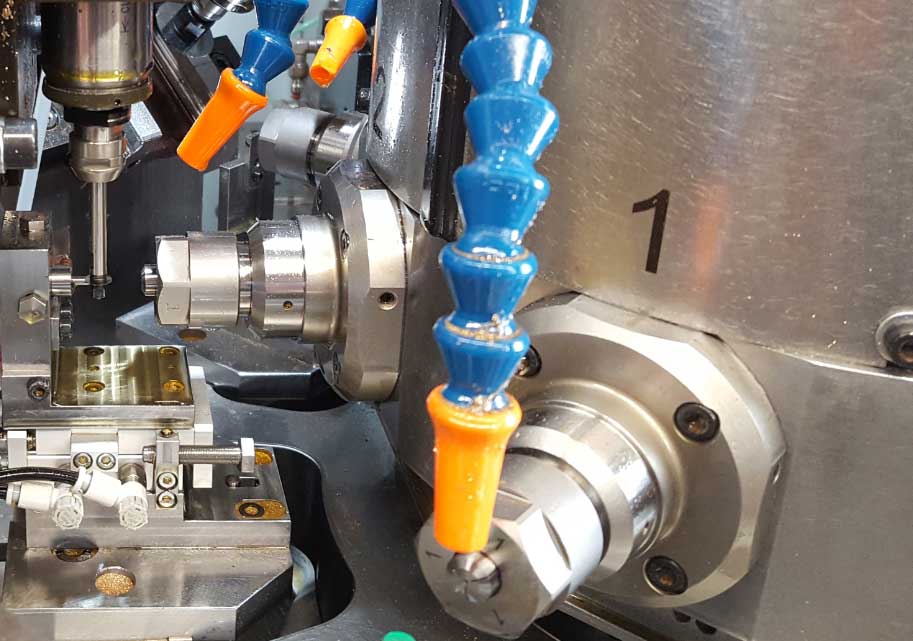

We have recently acquired a new generation of CNC transfer machine. This machine completes our wide range of ROL6 machines developed in-house ( 4 numerical machining stations ) and our ROL8 TORNOS ( 6 machining stations controlled by cams ).

This seconary operation machine has been developed in order to integrate our current collet feeding and clamping systems, thus preserving our reactivity and flexibility while being able to respond to a major trend of product miniaturization.

Each of the 6 numerical machining stations can be equipped if required with a tri-axis station and 2 spindles allowing greater machining possibilities for very complex parts. The positioning of the clamps (turret indexing defect included) is guaranteed within +/-0.009 mm in X and Y which makes it a reference of precision on the market.

This secondary operation machine has been designed to meet the highest speeds required by the electronics market.

It also benefits from the latest generation of software developed by our R&D team. The interface has been improved to display a greater amount of machine information that is essential to centralize and control our production in the best possible way.

This latest software version will be progressively integrated in the next few months on all our ROL6 machines.